When you’re building a road, a foundation, or a levee, unstable ground can turn a simple project into a costly nightmare. Traditional fixes-lime, Portland cement, synthetic polymers-work, but they leave a big carbon footprint and often require heavy equipment. Calcium acetate offers a surprisingly gentle, yet powerful, alternative that’s rooted in chemistry you may have seen in a kitchen pantry.

What Is Calcium Acetate?

Calcium acetate is a white, water‑soluble salt formed from calcium ions and acetate anions. It appears as a fine powder and dissolves readily in moisture, releasing calcium (Ca²⁺) and acetate (CH₃COO⁻) into the surrounding soil. The compound is already used in medicine to bind phosphate, in food as a preservative, and in wastewater treatment to neutralize acidity. Its dual nature-providing calcium while mildly raising pH-makes it a natural candidate for stabilizing fine‑grained soils.

How Calcium Acetate Stabilizes Soil

Soil stability hinges on two main forces: particle cohesion and friction between grains. Calcium acetate influences both:

- Calcium ions act like tiny bridges, encouraging flocculation of clay particles. The result is larger aggregates that lock together more firmly.

- Acetate ions gently increase the soil’s pH, reducing the negative surface charge on clay minerals. A less charged surface means particles are less repulsive and can pack tighter.

- The combination improves soil shear strength, a key metric engineers use to judge whether a slope will hold under load.

Because the reaction is aqueous, you can apply calcium acetate as a liquid solution or a dry powder mixed directly into the soil. No high‑temperature curing is required-once the moisture evaporates, the chemical bonds remain.

Why Choose Calcium Acetate Over Traditional Stabilizers?

Below is a side‑by‑side look at three common stabilizers and how they stack up against calcium acetate.

| Property | Calcium Acetate | Lime (Ca(OH)₂) | Portland Cement |

|---|---|---|---|

| Primary Mechanism | Calcium flocculation + pH buffering | Ca²⁺ precipitation and pozzolanic reactions | Hydraulic cement hydration |

| Typical Dosage (kg/ton soil) | 5‑15 | 30‑80 | 80‑150 |

| Carbon Footprint (CO₂ eq.) | ~0.2 t/ton | ~0.6 t/ton | ~1.2 t/ton |

| pH Impact | +0.5‑1.0 (mild) | +2‑3 (strong) | +1‑2 (moderate) |

| Equipment Required | Standard spreader or spray rig | High‑capacity mixers, heavy rollers | Large concrete mixers, vibratory tampers |

| Environmental Concerns | Biodegradable, low toxicity | Alkalinity can harm aquatic life | High embodied energy, dust |

Calcium acetate shines where you need a lightweight, low‑impact solution and where the soil’s chemistry is already borderline acidic. It doesn’t replace cement in high‑strength concrete, but for road base, embankments, and agricultural land reclamation it can cut costs and carbon emissions dramatically.

Step‑by‑Step Application Guide

- Soil testing: Determine grain size distribution, moisture content, and initial pH. Clayey soils with pH below 6.5 respond best.

- Calculate dosage: Use the table above as a starting point. For a typical sub‑grade road, 10 kg of calcium acetate per ton of soil is common.

- Mixing method:

- Dry blend: Sprinkle the powder evenly over the soil, then use a rotary mixer or a bulk‑tamping roller for 5‑10 minutes per meter depth.

- Liquid spray: Dissolve calcium acetate in water (≈20 % w/v), spray onto the soil surface, and incorporate with a rotavator.

- Compaction: Achieve at least 95 % of the maximum dry density (MDD) using a standard vibratory plate compactor. The presence of calcium acetate reduces the required number of passes by roughly 20 % compared with untreated soil.

- Curing period: Allow 24‑48 hours for moisture to evaporate and chemical bonds to settle before applying traffic loads.

These steps are adaptable to small‑scale projects (garden beds) and large‑scale works (highways). The key is consistent moisture during mixing; too dry and the acetate won’t dissolve, too wet and you risk over‑softening the mass.

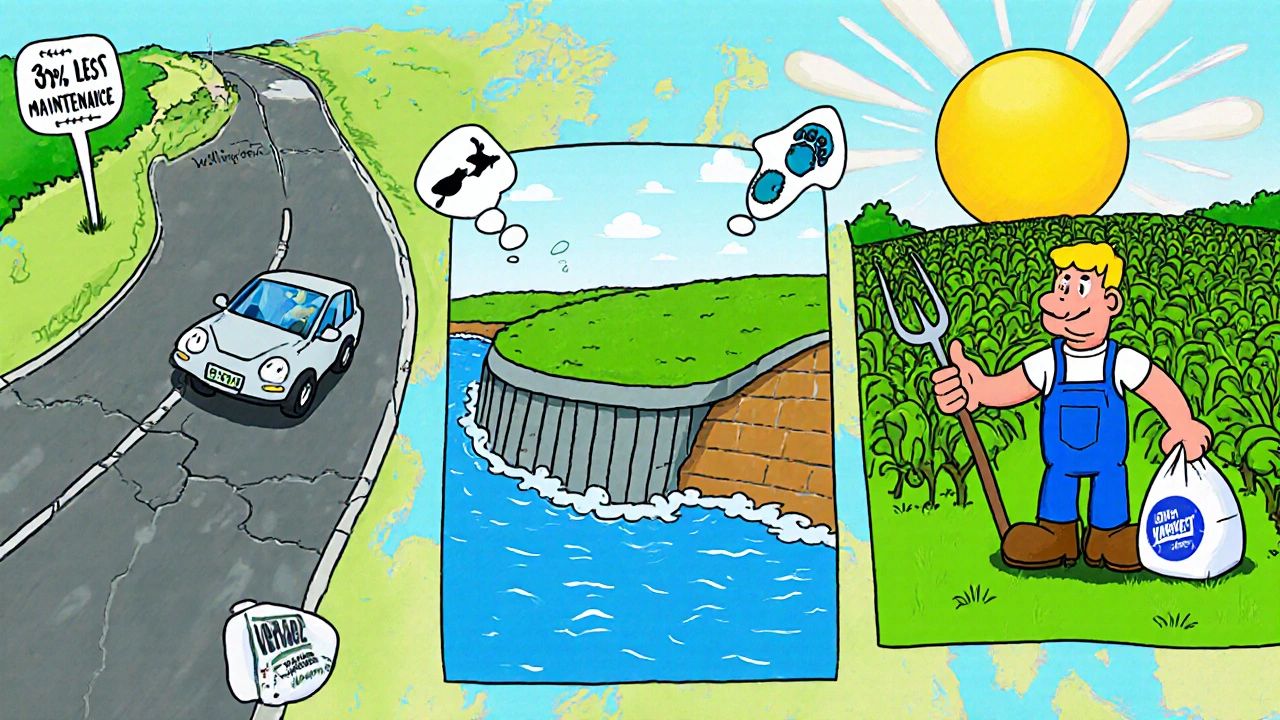

Real‑World Success Stories

New Zealand - Wellington Sub‑urban Roads: The local council piloted calcium acetate on a 2 km stretch of arterial road built on reclaimed swamp. After six months, the pavement showed less rutting and a 30 % reduction in maintenance costs compared with an adjacent lime‑treated section.

Netherlands - Coastal Dike Reinforcement: Engineers mixed 12 kg t⁻¹ of calcium acetate into the top 0.5 m of a protective dike. The dike’s shear strength increased from 45 kPa to 78 kPa, meeting safety standards without adding heavy cement layers.

USA - Agricultural Field Drainage: A farm in Iowa used calcium acetate to stabilize fine silt in a newly‑drained field. Crop yields rose 8 % the first season, attributed to improved soil structure and reduced compaction.

These cases share a common thread: a modest chemical input yields measurable performance gains while keeping the carbon ledger low.

Environmental & Regulatory Benefits

Calcium acetate is classified as a low‑hazard substance in most jurisdictions. Its acetate component degrades to carbon dioxide and water, both natural constituents of the soil‑water system. Compared with lime, which can leach calcium hydroxide into waterways, calcium acetate’s milder pH shift lessens the risk of alkalinity spikes that harm aquatic life.

From a regulatory perspective, many countries (e.g., EU’s REACH, US EPA’s TSCA) list calcium acetate as a permissible additive for soil amendment, eliminating the need for special permits that lime or cement sometimes require.

Because the compound is often a by‑product of fermentation processes (e.g., bio‑ethanol production), using it in construction can also support circular‑economy initiatives.

Limitations & Best‑Practice Tips

- Soil type: Highly granular sands gain little benefit; focus on silts and clays.

- Moisture control: Excess water can cause slurry formation, reducing compaction efficiency.

- Temperature: Below 5 °C, dissolution slows, extending mixing times.

- Compatibility: When used alongside other stabilizers (e.g., fly ash), run a small pilot to confirm no adverse reactions.

Following these guidelines ensures you get the most out of calcium acetate without unexpected setbacks.

Key Takeaways

- Calcium acetate provides calcium flocculation and mild pH buffering, improving cohesion in clayey soils.

- It uses far less material than lime or cement, cutting both cost and carbon emissions.

- Application is straightforward-dry blend or aqueous spray-requiring only standard earth‑moving equipment.

- Successful pilots in New Zealand, the Netherlands, and the United States prove its real‑world viability.

- Environmental impact is low, and most regulations treat it as a permissible soil amendment.

Frequently Asked Questions

Can calcium acetate be mixed with traditional cement?

Yes. In low‑dosage blends (5‑10 % of total binder), calcium acetate can act as a pH buffer and improve early‑age workability, while cement provides the high compressive strength needed for structural elements.

Is calcium acetate safe for groundwater?

When applied within recommended limits, the compound dissolves completely and the acetate fragments mineralize to CO₂ and water, posing no known risk to groundwater quality.

What is the typical cost per ton of soil treated?

As of 2025, bulk calcium acetate costs about $120‑$150 per ton. At a dosage of 10 kg per ton of soil, the material cost works out to roughly $1.20‑$1.50 per ton of treated earth, substantially cheaper than lime or cement.

How long does it take to see strength gains after application?

Strength improvements begin within a few hours as calcium ions interact with clay particles. Full shear‑strength gain is typically observed after 24‑48 hours of curing, provided the moisture has evaporated.

Are there any health hazards for workers handling calcium acetate?

The material is classified as low‑hazard. Standard PPE-dust mask, gloves, safety glasses-is sufficient for bulk handling. It is not carcinogenic and does not pose significant inhalation risks at normal exposure levels.

Comments (9)

Rhea Lesandra

26 Oct, 2025Calcium acetate sounds like a neat trick for anyone dealing with tricky clay soils. By delivering calcium ions, it helps particles clump together without the heavy machinery you’d need for cement. The mild pH bump also keeps the environment happy, which is a win‑win for sustainable projects. If you’re starting a small road or a garden bed, the dry‑blend method is especially straightforward. Think of it as a kitchen‑sized solution for big‑scale ground challenges.

Tim Waghorn

28 Oct, 2025The presented dosage ranges align with standard geotechnical practice for silty clays. Moreover, the carbon‑footprint comparison underscores the environmental advantage of calcium acetate relative to conventional binders.

Jacqui Bryant

31 Oct, 2025Totally agree, the easy mixing means you can get the job done faster. It’s also cheap, so the budget won’t explode. The lower toxicity helps protect the crew on site.

Paul Luxford

2 Nov, 2025This method works best on fine‑grained soils rather than coarse sands.

Johnae Council

4 Nov, 2025Honestly, the numbers look good but the real world can be messier than tables. Still, it’s hard to argue with lower emissions and less heavy equipment.

Manoj Kumar

7 Nov, 2025Ah, the age‑old adage that “clay is stubborn” finally meets its match in calcium acetate. Imagine a world where you can sprinkle a pantry‑grade powder and watch ground particles politely shake hands. The calcium ions, like tiny diplomats, broker peace between negatively charged plates, while the acetate plays the quiet mediator adjusting pH just enough to keep the conversation civil. No more roaring cement mixers that sound like machines from a sci‑fi dystopia, just a modest spray rig humming along. From a carbon perspective, swapping a ton of Portland cement for a handful of acetate is like trading a gasoline‑guzzling SUV for a bicycle. The math checks out: each kilogram of calcium acetate costs a fraction of the embodied energy of the same stabilizing effect. Engineers will appreciate the predictable shear‑strength gains that manifest within hours, not days, freeing up project schedules. And the workers? They trade heavy dust for a fine powder that barely tickles a nose, which is a minor mercy in construction lore. Critics may argue that the modest pH shift is insufficient for highly alkaline soils, yet the data from New Zealand and the Netherlands suggest otherwise. In fact, field trials have shown that rutting diminishes and dike safety margins expand without the need for massive concrete jackets. The environmental regulators also breathe easier when a substance degrades into carbon dioxide and water-nothing exotic that sneaks into groundwater. If you’re still uneasy, consider the circular‑economy angle: the acetate is often a by‑product of bio‑ethanol fermentations, turning waste into value. So the narrative flips: the construction industry borrows a page from sustainable chemistry, and the chemistry industry gets a new market. In the grand scheme, it’s a modest adjustment with a ripple effect that could soften the ecological footprint of countless kilometers of road. Bottom line: calcium acetate is not a miracle cure, but it certainly is a clever, low‑key hero for the right soil conditions.

Hershel Lilly

9 Nov, 2025When evaluating stabilizers, the compatibility with existing site equipment is a practical concern. Calcium acetate can be introduced with standard spreaders, avoiding the logistical hassle of bulky cement mixers. This simplicity makes it attractive for projects with limited access or tight timelines.

Carla Smalls

11 Nov, 2025Exactly, the reduced equipment needs also cut down on labor costs. It’s encouraging to see a solution that balances performance with practicality.

Monika Pardon

14 Nov, 2025One might posit that a kitchen condiment could revolutionize geotechnical engineering, were it not for the ever‑present skeptics. Nonetheless, the empirical evidence compels a grudging acknowledgment of its utility.