What Noise-Induced Hearing Loss Really Is

Imagine working in a factory where the machines never stop roaring. After a few years, you start noticing you can’t hear your kids clearly when they talk from across the room. You turn up the TV louder. People say you’re not listening. But you’re not ignoring them-you can’t hear them well anymore. That’s noise-induced hearing loss (NIHL). It doesn’t come from aging. It doesn’t come from illness. It comes from your job.

NIHL happens when loud noise destroys the tiny hair cells in your inner ear. These cells turn sound into signals your brain understands. Once they’re gone, they don’t grow back. That’s why NIHL is permanent. And here’s the kicker: it’s also completely preventable. You can’t undo the damage, but you can stop it before it starts.

According to the CDC, 22 million U.S. workers are exposed to dangerous noise levels every year. The Bureau of Labor Statistics says NIHL is the second most common occupational illness in the country. It’s not rare. It’s not accidental. It’s predictable-and preventable.

How Loud Is Too Loud?

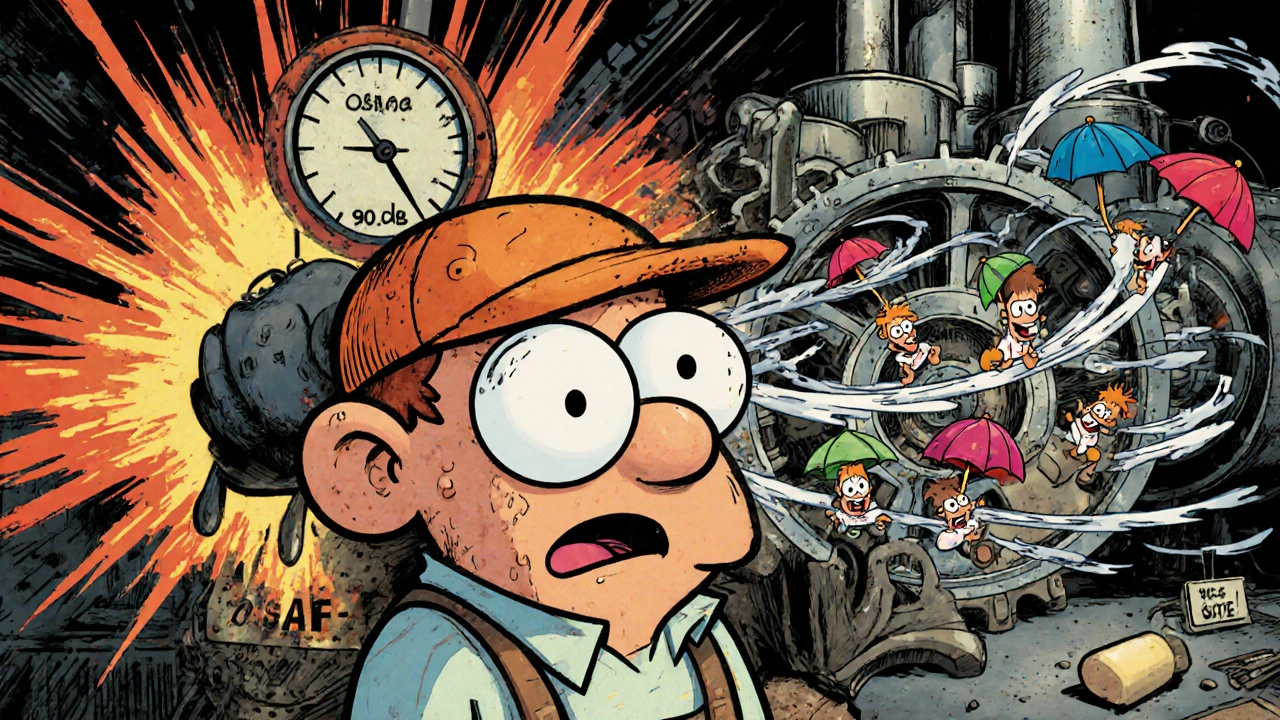

Decibels (dB) measure sound. Normal conversation is about 60 dB. A lawnmower hits 90 dB. A jackhammer? 130 dB. But here’s what most people get wrong: it’s not just how loud it is. It’s how long you’re exposed.

OSHA, the federal agency that sets workplace rules, says you can be exposed to 90 dB for up to 8 hours a day. But NIOSH, the health agency that actually studies this stuff, says that’s too high. They recommend a limit of 85 dB. Why the difference? Because at 85 dB, damage starts. That’s not a safe level-it’s the line where hearing begins to break down.

And it gets worse fast. Every time the noise goes up 3 dB, your safe exposure time cuts in half. So at 88 dB, you’re only safe for 4 hours. At 91 dB, just 2 hours. At 100 dB? Only 15 minutes. Most construction workers, factory line operators, and miners hit these levels daily. And they don’t even realize it.

Why Hearing Protection Often Fails

You’ve probably seen workers wearing foam earplugs. They look cheap. They’re cheap. And they often don’t work the way they’re supposed to.

Lab tests say foam earplugs can block 30+ dB of noise. Real life? More like 15-20 dB. Why? Because most people don’t insert them right. A 2017 Cochrane review found that 75% of workers put in foam earplugs incorrectly. They roll them too tight. They don’t wait for them to expand. They pull them out too soon. The result? Half the protection they’re supposed to get.

And then there’s comfort. Workers in Reddit’s r/occupationalhealth say they take earplugs out because they can’t hear coworkers or warning signals. Some say the plugs hurt after two hours. Others say management gives them the cheapest ones, then wonders why they don’t wear them.

Custom-molded earplugs work better. They’re shaped to your ear, fit snugly, and block 25-30 dB consistently. But they cost more. And most companies won’t pay for them unless they’re forced to.

The Real Solution: Stop the Noise at the Source

Wearing earplugs is like wearing a raincoat in a flood. It helps-but it’s not the best fix. The best fix is to turn off the rain.

That’s what engineering controls do. They reduce noise before it reaches your ears. Examples? Installing acoustic enclosures around noisy machines. Adding sound-dampening panels to walls. Using quieter tools. Replacing old air compressors with newer, quieter models.

NIOSH’s 2015 mining study showed noise dropped from 98 dB to 82 dB just by switching out old drills. Workers didn’t just hear better-they reported less fatigue and better focus. That’s not just about hearing. It’s about safety, productivity, and mental health.

And here’s the thing: engineering controls work. They’re the most reliable part of hearing protection. But they’re also the hardest to get. They cost money upfront. They require planning. They need management buy-in.

That’s why so many companies skip them. They’d rather hand out foam plugs and call it done.

What Companies Should Actually Be Doing

NIOSH’s 5-step plan for preventing hearing loss isn’t complicated. But few companies do it right.

- Measure the noise. Use a calibrated sound level meter. Don’t guess. Don’t rely on old data. Test every job site, every year.

- Reduce noise at the source. Buy quieter equipment. Install barriers. Fix worn parts that rattle. NIOSH’s ‘Buy-Quiet’ database lists over 1,200 low-noise tools and machines.

- Fit hearing protection properly. Don’t just hand out earplugs. Train workers. Test their fit. Use Real Ear Attenuation at Threshold (REAT) measurements. Custom earplugs should be offered, not just foam.

- Test hearing every year. Baseline audiograms within 6 months of starting. Annual tests at 500, 1000, 2000, 3000, 4000, and 6000 Hz. A shift of 10 dB at 2000-4000 Hz means damage is happening.

- Train workers constantly. One 10-minute talk at orientation isn’t enough. Workers need reminders, demonstrations, and feedback. Training improves earplug use-but only if it’s repeated.

Companies that do this right see results. A 2021 NIOSH analysis found every $1 spent on a full hearing conservation program returns $5.50 in reduced workers’ comp claims.

Who’s at Risk-and Why It’s Getting Worse

It’s not just factory workers. Construction workers? 22% are exposed to dangerous noise. Miners? 17%. Farmers? 15%. Even warehouse workers using forklifts or pallet jacks are at risk.

And the problem is growing. California passed new rules in 2023 requiring employers to try engineering controls before relying on earplugs. The EU lowered its exposure limit to 80 dB in 2024. The U.S. is still stuck at 90 dB.

OSHA’s 2023 National Emphasis Program targets construction, manufacturing, and agriculture-where NIHL rates are highest. They’re doing 5,000+ inspections a year. But compliance is low. Only 49% of manufacturing plants follow the rules. And 30% of workers in those industries already have hearing loss.

Meanwhile, the global hearing protection market is worth $1.27 billion and growing. That’s a lot of money spent on fixing a problem that could’ve been avoided.

What You Can Do Right Now

If you work in a noisy environment:

- Ask your employer: “Has this area been tested for noise levels?”

- Check if your earplugs are the right type. Foam plugs are fine if used correctly-but custom ones are better.

- Learn how to insert them properly. Roll the plug thin, pull your ear up and back, insert slowly, hold for 20 seconds.

- If you can’t hear someone talking from 3 feet away, the noise is too loud.

- Get your hearing tested annually. Don’t wait until you notice a problem.

If you’re a manager:

- Stop treating hearing protection as the only solution.

- Invest in quieter tools. Use NIOSH’s Buy-Quiet database.

- Pay for fit-testing. It’s not expensive, and it works.

- Let workers help choose hearing protection. When they have a say, they wear it.

- Track your hearing loss claims. If you’re paying out more than $14,700 per case, you’re losing money.

The Bottom Line

Noise-induced hearing loss isn’t inevitable. It’s not a normal part of aging. It’s not something you just have to live with. It’s caused by preventable exposure. And every day that goes by without action, more workers are losing their hearing.

The science is clear. The tools exist. The money saved is real. The only thing missing is the will to act.

Protecting hearing isn’t just about compliance. It’s about keeping people connected-to their families, their jobs, their lives. And that’s worth more than any cheap pair of earplugs.

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t regenerate. That’s why NIHL is permanent. But it’s also why prevention is so critical-once the damage is done, there’s no cure.

Is 85 dB really dangerous for hearing?

Yes. While OSHA allows up to 90 dB, NIOSH and health experts agree that 85 dB is the threshold where hearing damage begins. At this level, exposure over 8 hours a day can cause permanent hearing loss over time. Many workers are exposed to this level daily without realizing the risk.

Do earplugs really work in noisy workplaces?

They can-if used correctly. Foam earplugs often provide only 15-20 dB of protection in real use because most people insert them wrong. Custom-molded earplugs offer more consistent protection (25-30 dB) and are more comfortable for long shifts. Fit-testing with REAT measurements ensures they’re working as intended.

What’s the difference between OSHA and NIOSH noise limits?

OSHA’s legal limit is 90 dB for 8 hours with a 5-dB exchange rate. NIOSH recommends 85 dB with a 3-dB exchange rate. That means under OSHA, you can be exposed to 16 times more noise energy than NIOSH says is safe. NIOSH’s guidelines are based on preventing hearing loss, not just meeting legal minimums.

Why don’t workers wear hearing protection consistently?

Common reasons include discomfort, difficulty hearing coworkers or warning signals, poor fit, and lack of training. Many workers are given cheap foam plugs that don’t fit well or cause irritation. When management doesn’t prioritize fit-testing or let workers choose their own protection, compliance drops below 40%.

How much does a hearing conservation program cost?

Companies typically spend $150-$300 per employee annually on full programs including testing, training, and equipment. But the return is strong: NIOSH found $5.50 saved in workers’ compensation claims for every $1 invested. The average workers’ comp claim for hearing loss costs $14,700.

Are there quieter tools available for construction and manufacturing?

Yes. NIOSH’s Buy-Quiet initiative lists over 1,200 tools and machines that produce 3-15 dB less noise than standard models. Examples include quieter saws, drills, and compressors. Switching to these tools is more effective than relying on earplugs alone.

Can hearing loss from noise be detected early?

Annual audiometric testing can detect early shifts in hearing-usually a 10 dB loss at 2000-4000 Hz. New research is exploring biomarkers that could detect damage before it shows up on a hearing test, but those aren’t widely available yet. Regular testing remains the best early warning system.

Comments (9)

Jennifer Walton

14 Nov, 2025I used to work in a warehouse. They gave us foam plugs. I took them out after 20 minutes. Couldn't hear the forklifts. Guess what? I got tinnitus. Now I wear custom ones. They cost $150. Worth every penny. No more ringing.

Kihya Beitz

16 Nov, 2025Oh wow. Another corporate PSA about earplugs. Next they’ll tell us to drink more water to avoid heatstroke. Meanwhile, the boss is still using a 1998 air compressor that sounds like a dragon with a sinus infection. Engineering controls? Nah. Let’s just make the workers pay for their own hearing aids.

Jonathan Dobey

17 Nov, 2025You know what’s really being suppressed here? The fact that the entire industrial complex is built on the slow, silent murder of working-class senses. They don’t care if you go deaf-they care if you show up. The 85 dB limit? A myth propagated by NIOSH to make OSHA look bad. The real agenda? Keep you docile, distracted, and dependent on hearing aids manufactured by the same conglomerates that profit from your silence.

ASHISH TURAN

17 Nov, 2025In India, many factories don’t even have noise meters. Workers get one pair of earplugs for a year. Sometimes they’re reused. No training. No testing. I’ve seen guys with 30 dB hearing loss at 28. It’s not just an American problem. It’s a global failure of basic dignity.

Ryan Airey

18 Nov, 2025Let’s cut the fluff. If your company is still using foam plugs as the primary solution, they’re criminally negligent. I’ve audited 12 plants. 11 of them didn’t even have a baseline audiogram on file. That’s not negligence-that’s malice with a paycheck. Report them. File an OSHA complaint. Your ears are not disposable.

Edward Ward

19 Nov, 2025I’ve been in manufacturing for 22 years, and I’ve seen everything-from the guy who thought ‘earmuffs were for winter’ to the supervisor who told us ‘if you can’t hear the machine, you’re not paying attention.’ But here’s the thing: when we finally installed acoustic panels around the stamping press, productivity went up 12%, and absenteeism dropped. People weren’t exhausted all day. They could communicate. They felt respected. It’s not just about hearing-it’s about humanity. And yes, I cried when I heard my daughter’s laugh clearly for the first time in five years. Don’t wait for that moment to be your wake-up call.

Andrew Eppich

20 Nov, 2025It is morally indefensible to allow workers to be exposed to hazardous noise levels. The cost of prevention is negligible compared to the cost of human suffering. Employers have a duty-not a choice-to provide safe working conditions. The fact that this even needs to be debated is a reflection of our societal decay.

Jessica Chambers

22 Nov, 2025I’m a supervisor. We switched to custom plugs last year. Workers picked their own colors. Now they wear them. We do fit-testing every 6 months. No one’s complaining. Also, we bought a quieter drill. It cost $2K. We saved $18K in claims this year. 😊

Shyamal Spadoni

23 Nov, 2025you know what they dont tell you? the earplug companies are owned by the same corp that makes the loud machines. its all a racket. they make the noise, then sell you the fix. and the gov? theyre in on it. osha is just a puppet. niosh? theyre the ones pushing the 85db lie to make you think its safe. but its not. its a distraction. the real solution? shut down the factories. go live in the woods. or better yet, just stop working. why let them ruin your ears for a paycheck? the system is rigged. they want you deaf, dumb, and obedient. i know this because i read the secret memos. (ok maybe i didnt. but it makes sense.)